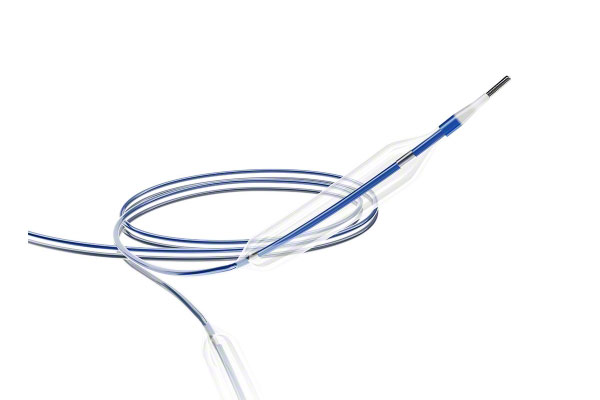

At present, balloon catheter with good bending performance and smooth tip design has been used in the dilatation therapy of a variety of diseases. There are mainly two kinds of high-quality balloon materials on the market, one is Nylon, the other is PEBAX. They can smoothly enter the position of semi occlusion or complete occlusion. The design of developing ring can accurately determine the position of the balloon when used. The structure of the balloon dilatation catheter will be introduced in detail below.

1. Balloon Tip

The size and performance parameters (such as diameter, length, and hardness) of the tip of the balloon catheter can directly affect its ability to pass through the lesion. Take Selethru® PTCA Balloon Dilatation Catheter as an example. Tip laser forming technique makes the balloon with a small entrance, which can enhance the performance of crossing the stenosis; Soft tapered tip is designed to enhance the traceability of the catheter with the guidewire. In general, a balloon dilation catheter with a short hard tip is suitable for the treatment of severe stenosis lesions, while the long soft tip catheter is more suitable for the treatment of tortuous lesions.

2. Main Structure

The material of the balloon has a great influence on the compliance of the balloon catheter. The balloon compliance of PET is lower than that of POC. The semi-compliant balloon is usually made of PEBAX, while the non-compliant balloon is usually made of Nylon. The 3-wings balloon fluting ensures that the balloon has a minimum profile to cross the stenosis easier. The material of the balloon also affects the retraction performance of the balloon. Retraction performance refers to the recovery ability of balloon diameter after balloon expansion and suction. It is one of the indexes to evaluate the crossability of the balloon. Nowadays, the super-lubricity hydrophilic coating is widely used on the surface of the balloon for superior delivery performance. Moreover, the advanced laser bonding technology ensures the balloon and the catheter smooth transition connection, which makes better crossability.

3. Integrated Shaft System

The domestic well-known shafts for balloon catheters are divided into polymer materials and metal materials. The shaft with polymer material can reduce the friction while advancing, and the shaft with metal material can have a better delivery performance. The integrated shaft system of Selethru® Balloon Dilatation Catheter is made of Hypo tube. It is a polymer-coated stainless-steel tube. The steel construction is designed to optimize proximal push ability with a smooth transition to a distal shaft. Meanwhile, a hydrophilic coating is applied to the outside surface of the distal shaft to reduce friction force with the vascular wall.

To sum up, the main composition of the balloon dilatation catheter includes a tip, balloon, and integrated shaft system. Besides, as the link between the shaft system and the balloon, the connecting section has a great impact on the delivery performance and bending resistance of the balloon. The central steel wire is usually placed in it to enhance the supporting force, to improve the delivery performance and bending resistance.